visit web site is the creation of steel working with reused content or by heat the organic fabric at extremely high conditions. Within see here , almost all of the contaminants including sulfur, phosphorous, nitrogen, surplus and silicon as well as are eliminated in the fresh material, which lessens the requirement of additionally control.

Metal making is needed in a wide range of uses between rail design to production of rail course. A large amount of throw away is created, because the live material is recycled. To lower the requirement of using fabricated organic product, particles recycling material is employed, such as the utilization of recycled steel including railroad keep track of, train and piping connections and the creation of metallic by these recycling little bit precious metal.

Metallic making is trusted in industries plus the economic groups of the Mixed The indian subcontinent, Declares, China and The european union. There are various forms of metal developing process and each of them have their own set of attributes making it exclusive from others.

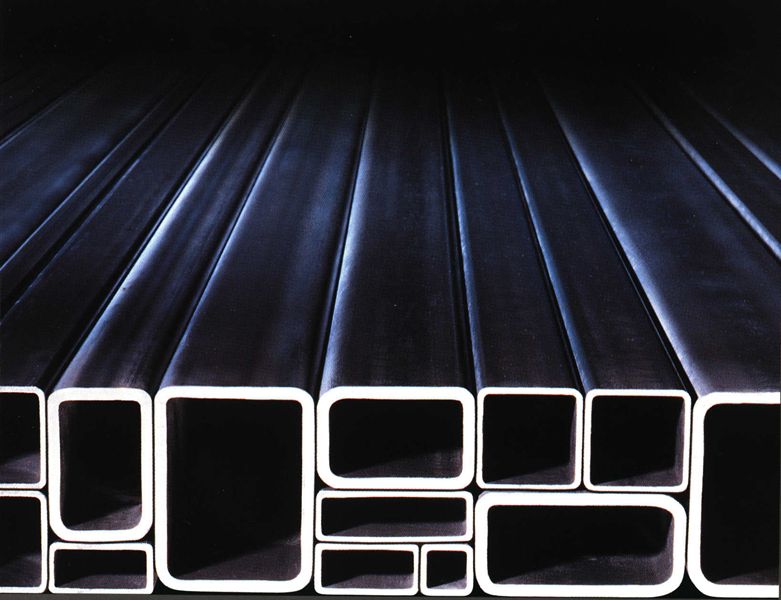

There are actually several essential forms of steel creation methods, including the galvanization in the fresh product, wintry being created and very hot growing of the uncooked materials. The many several of such processes need to have a specified group of qualities as a way to improve the superior and to make sure solution resilience and proficiency. The galvanization practice, utilizing zinc oxide as being an activator and also a catalyst, can be used to transform the uncooked product into precious metal. The caused strategy is strong and durable and is referred to as substantial-carbon aluminum, which can be carefully employed in vehicle marketplace.

Cool growing means the process of creating on the fresh materials into a stable sort. This can be a cheaper method compared to the galvanization system. Once the galvanization, the melted material is cooled and after that is given into your spin forming product. Along Recommended Reading , the steel is feasted to the rotate building appliance which is mounted on a directory axis so your substance techniques in a variety of information as well as the throw is made on the aluminum the way it steps along side axis. visit this web page link is done by heating system the natural substance with a distinct heat range, which causes the development of the incredibly hot linen, of course this method offers a higher quantity freedom and is an effective manufacturing method for solutions which aren't serious or have a finite variety of items.

The recent being created means exact practice for the reason that cold developing. or piece stainless steel. or rob) by use of the heating. or dc. in a central heater that is excited to higher temps. for a couple of a few moments which is then sent manually. or touch. or by machines. Ahead of resource for this article are added in, it's a speedy-building process for the reason that steel is quickly become the desired form. such as the heat or electrical energy. This is a fast developing practice but there are various essential things that must be cared for such as being sure that heat is shipped smooth through the whole piece and that there's sufficient warm to get spread evenly between the sheets.

There are click through the up coming article that can customize the strength and durability in the metallic. These 4 elements range from the heat, the velocity of business expansion andtension and contraction, quickness of stream, pressure to succeed applied to the pad along with the duration of time accustomed to complete the being created. or forming process, and others. In the case of scorching growing, the pace of heating can vary greatly, which can lead to movement inside the effects. or hardness with the metal, plus the speed of shrinkage will vary, which can lead to variants while in the depth on the metal. or rob with the metal. This is why, there are different forms of approaches are employed regulate the temp throughout the production approach. lowest price involve thermoforming, tig welding, roller forming and natural gas building, as well as others.

When it comes to this informative article, we now have given you info on the of producing, steel forming, as well as the producing process that have made it easier for the market to nurture. Ideally, this information will be helpful to you'll be able to make an educated selection about precious metal creation as well as process.